#

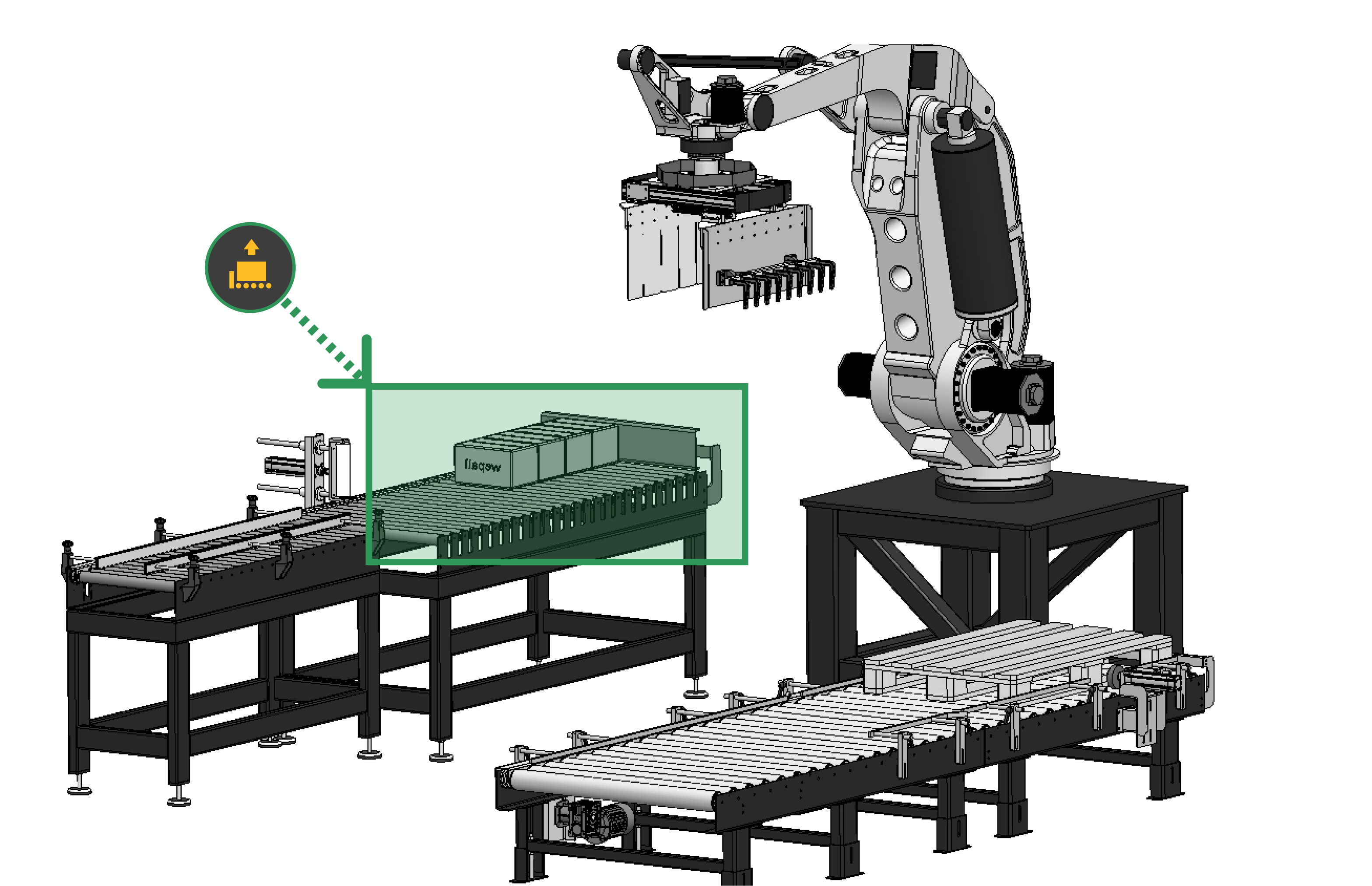

Station Preset - Pick Station

#

Description

Corresponds to the pickup station where the product to be palletized will be picked up, also known as pickup.

#

Assignment of variables

The variables of this preset will be modified according to the type of End Effector Tool selected.

#

Variables

#

Name

User-defined name to identify the pickup.

#

[X,Y,Z,R]

Coordinates of the point where the robot will pick up the product in the pick under normal conditions.

For more information, see the section on obtaining coordinates in this manual.

An error in the transcription of the data in this section may cause collisions.💥

#

Inverted [X,Y,Z,R]

Coordinates of the inverted point where the robot will pick up the product. In this position, the fixed paddle must be located on the opposite side of the pick position. It can be used on all grippers except fork grippers.

For more information on how to obtain coordinates, see the section on obtaining coordinates in this manual.

An error in the transcription of the data in this section may cause collisions.💥

#

Vacuum gripper

In the case of vacuum grippers, both the pick height and the inverted pick height are dynamic, i.e. depending on the product height.

The value of pick Z andy inverted pick Z will be with the suction cups attached to the pickup.

#

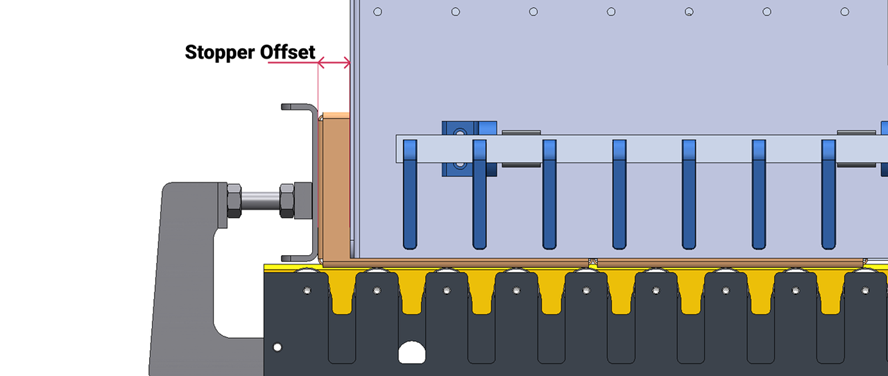

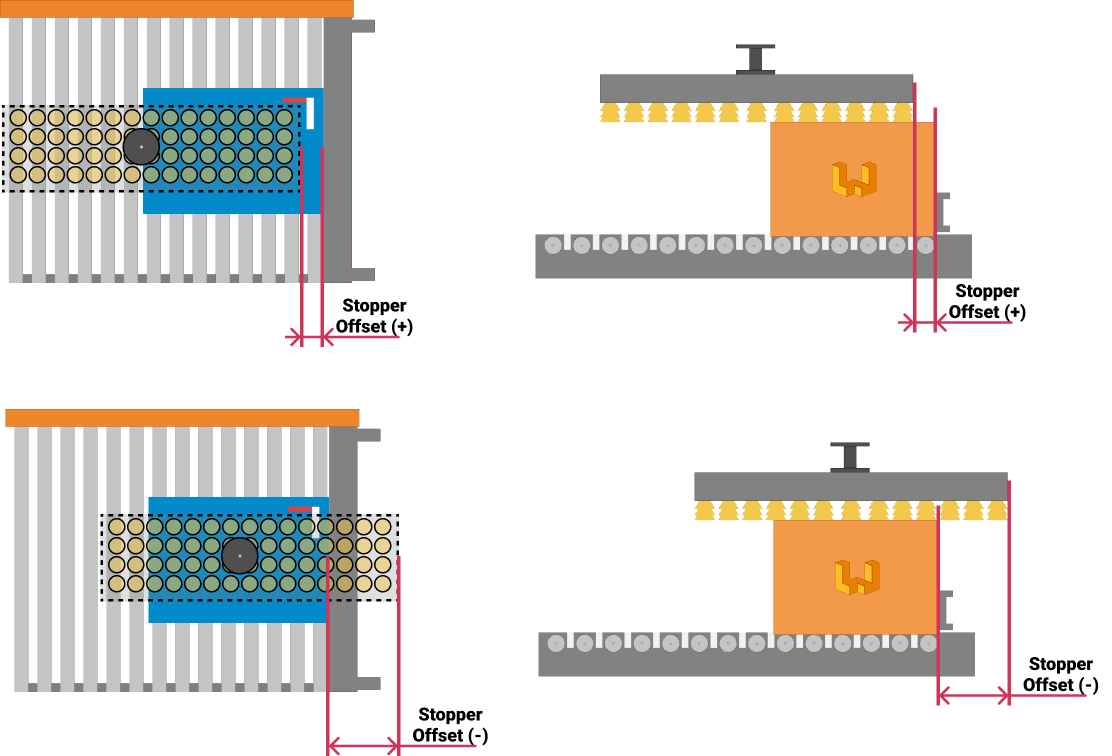

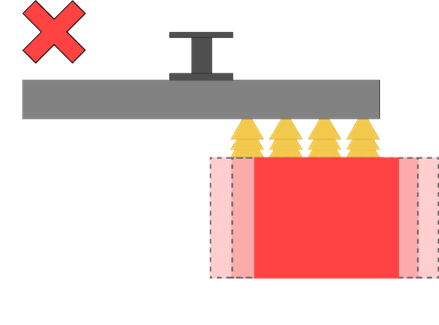

Stopper Offset

Clearance between the gripper and the stopper at the pick point. This is the distance that the product will protrude with respect to the gripper. Indicated in millimeters. This value adjusts the reference left on the pallet.

For more information about the pick point, see node station, Pick Station.

An incorrect setting of this value can cause collisions with products already on the pallet. 💥

Changing this value does not modify the pick coordinates in any way.

#

Inverted Stopper Offset

Clearance between the gripper and the stopper at the inverted pick point. This is the distance that the product will protrude with respect to the gripper. Indicated in millimeters. This value adjusts the left reference on the pallet.

For more information about the pick point, see node station, Pick Station.

#

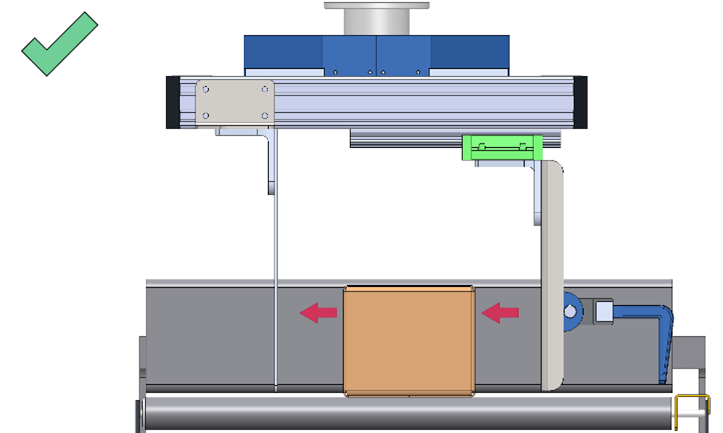

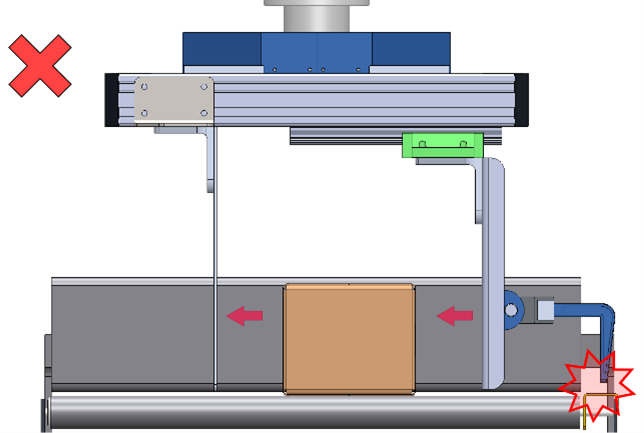

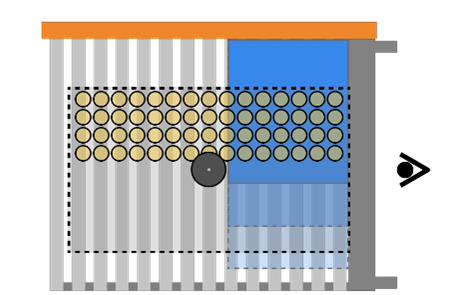

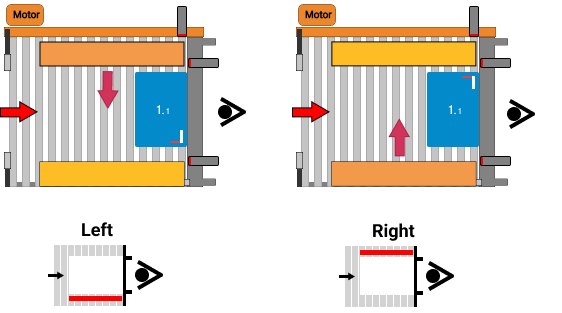

Reference side

Position indicator of the side where the fixed paddle of the grapple (physical or virtual) would be located in the pick position. Taking as a point of view the product entry to the pickup, it can be located to the right or to the left of the product.

If this value is set incorrectly, the pallet will be positioned incorrectly on the pallet.

#

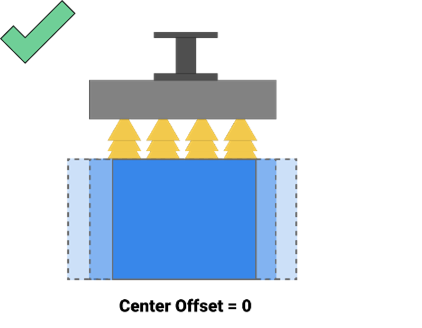

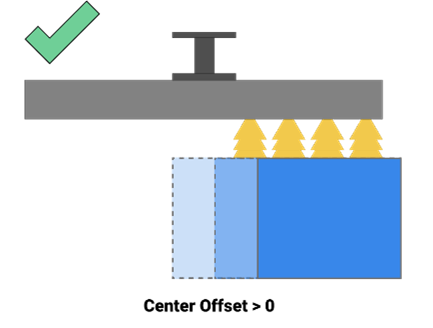

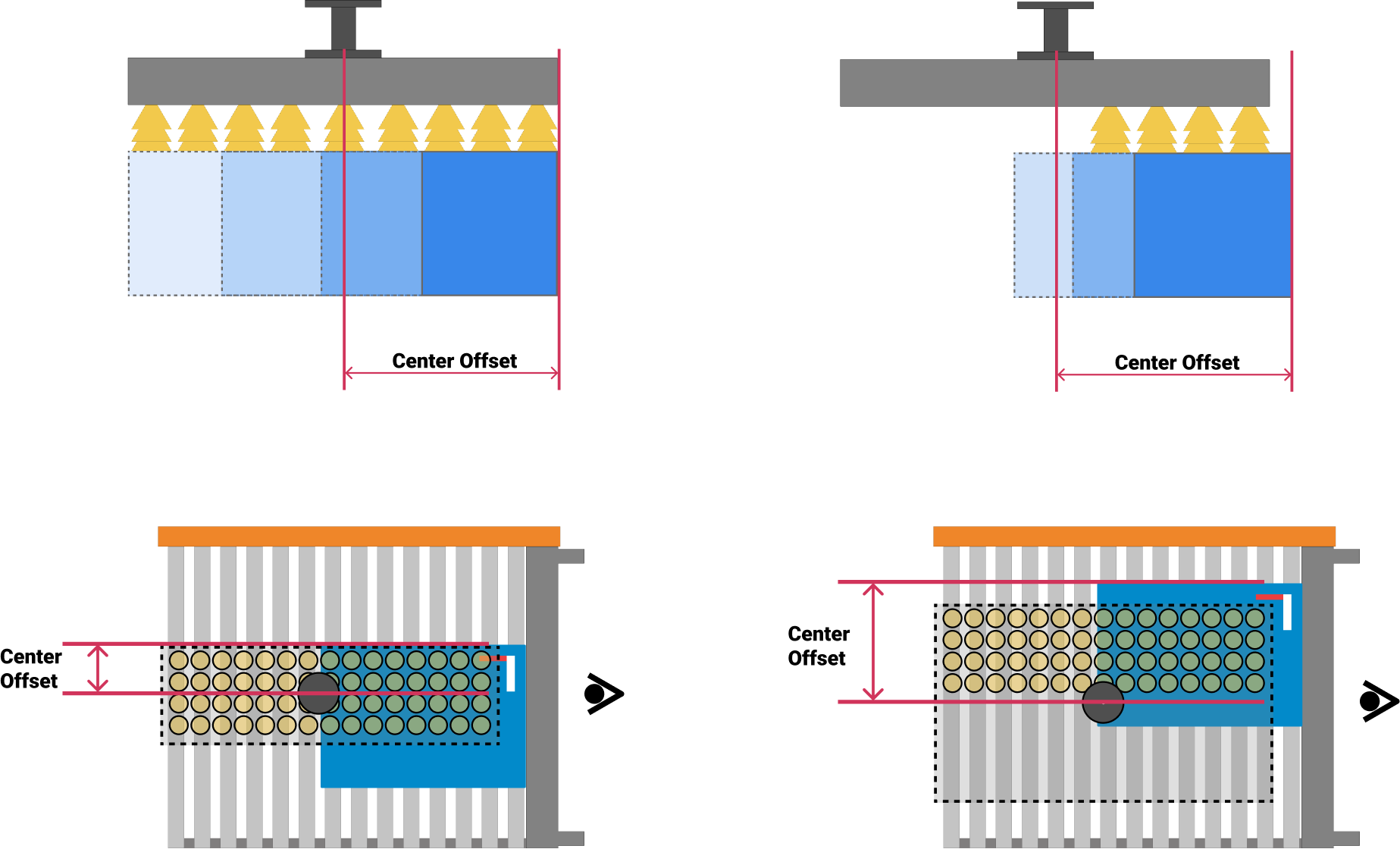

Center Offset

Clearance distance between the center of a vacuum gripper flange and a fixed reference (usually one of the pickup guides), at the pick coordinates. Indicated in millimeters.

With a value of 0, the software will be told that the product will always be symmetrical with respect to the center of the robot flange.

In the event that the suction system is off-center with respect to the center of the flange, a mechanical element must be provided to align the products so that a fixed reference is available.

In case the flange is off-center and the product does not have a fixed reference, this possibility is not provided for in the Wepall software.

Some examples of application of this parameter are shown below.

#

Inverted Center Offset

Clearance distance between the center of a vacuum gripper's mating flange and a fixed reference (usually one of the pickup guides), at the inverted pick coordinates. Indicated in millimeters.

Follow the instructions given in the previous section center offset.

#

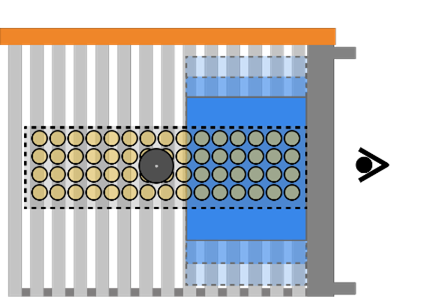

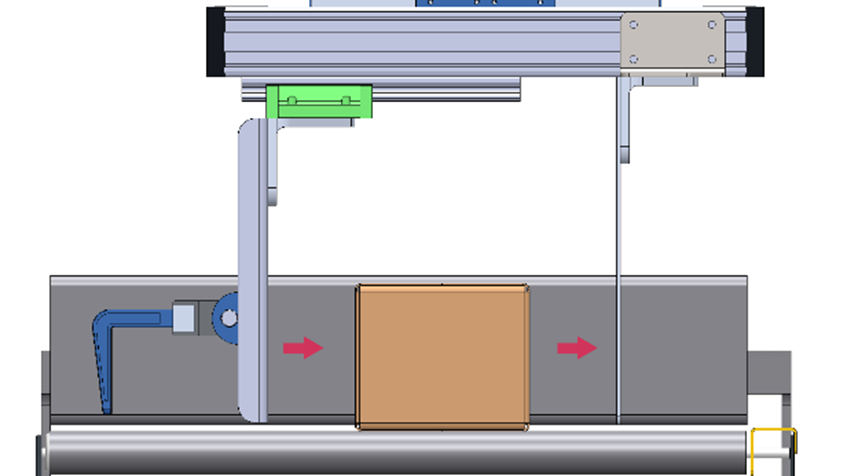

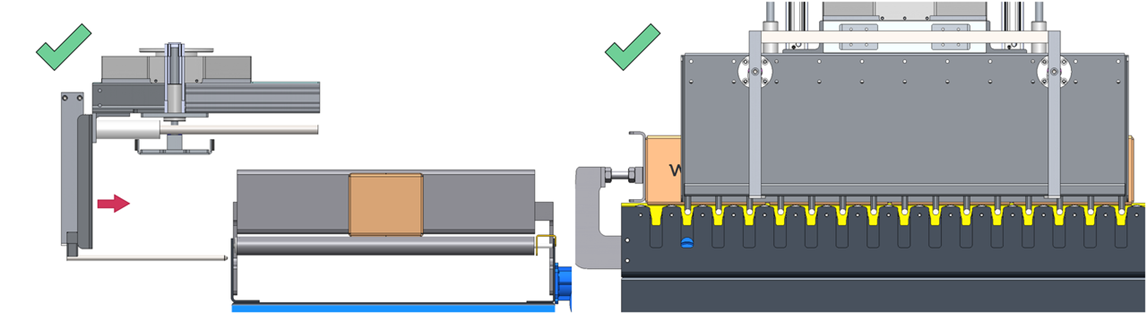

Wait [X,Y,Z,R]

Coordinates of the robot waiting point used in the fork grips, until the confirmation of ready product is received at the pickup.

For more information on how to obtain coordinates, see the section on obtaining coordinates in this manual.

The alignment of the gripper must be precise. Since the approach of the gripper is made from the side to the pickup, and if we do not have it well adjusted, the fingers of the fork can collide by not accessing the slots, or with the products deposited on it.

#

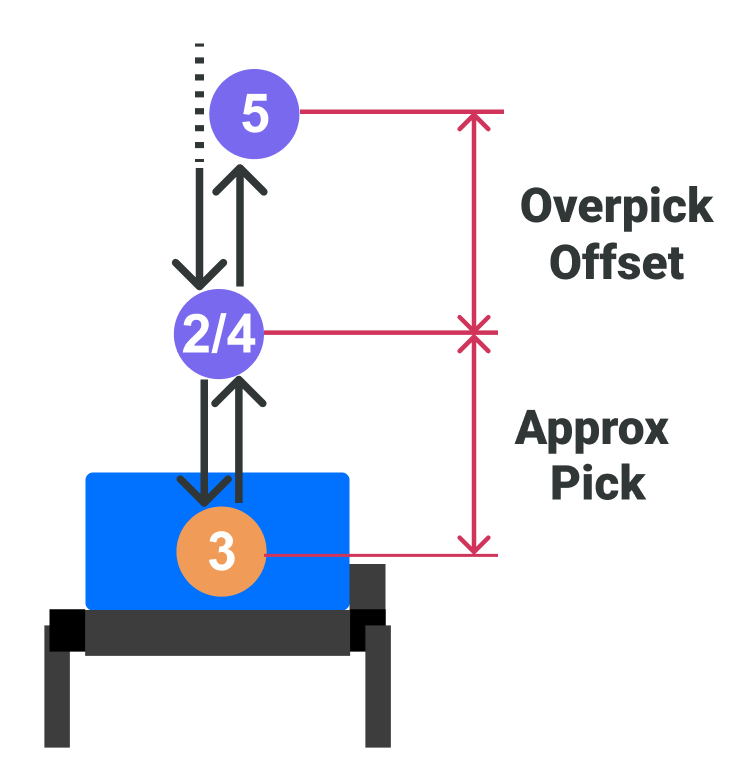

Approx Pick

Height along the Z-axis, which will raise the gripper once the product is picked up. Indicated in millimeters

This height must be greater than the height of the product.

This height must allow the product to enter the pickup without colliding with any mechanical element of the grapple, or of the product it carries, as well as with any physical element present in the pickup.

#

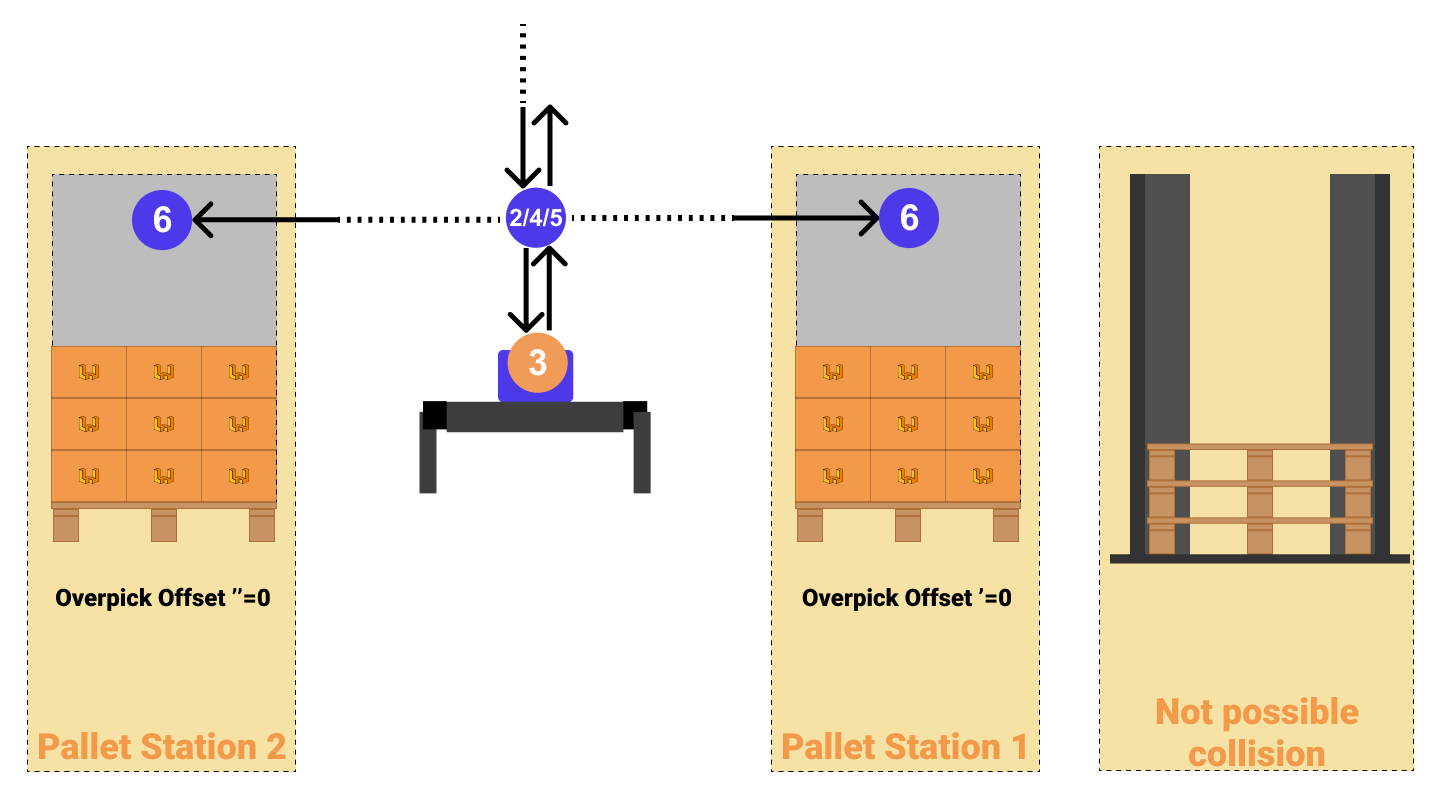

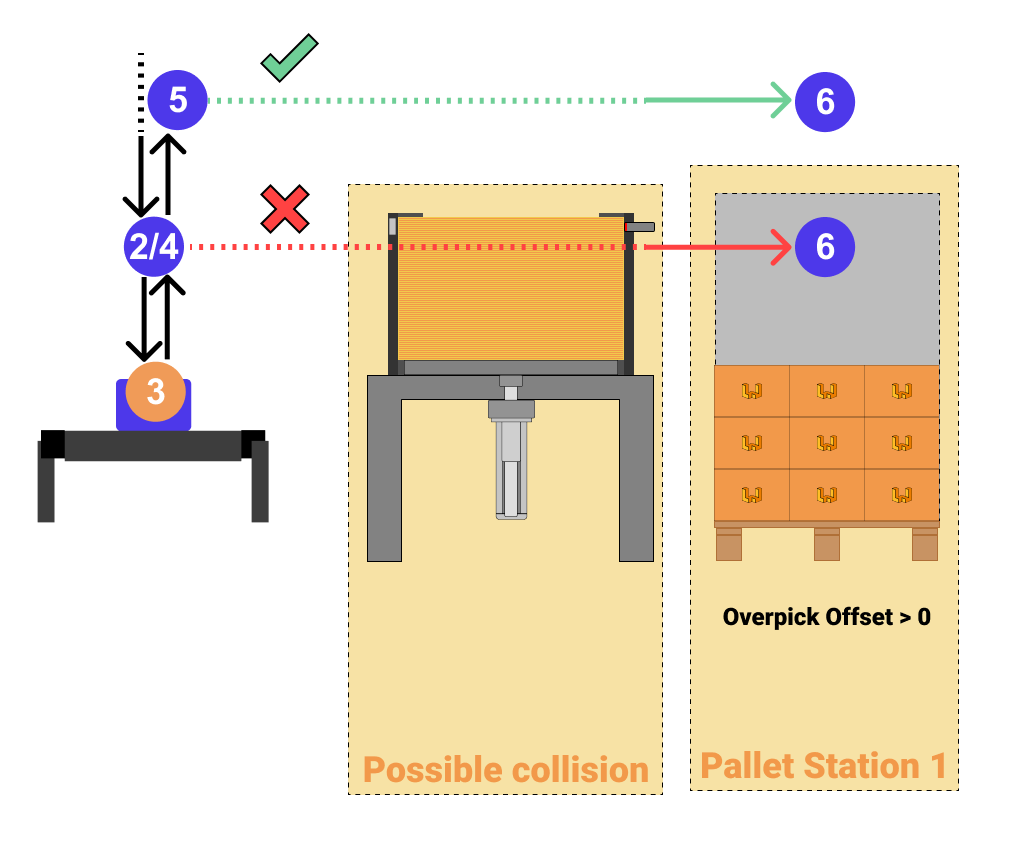

Overpick Offset

Indicates the minimum offset between point 3 and point 4. Since the height of point 4 is dynamic, if the layer height is higher than the defined value, it will adapt to a higher height. If it is lower, it will take the minimum value set.

If left with a value of 0, the minimum height of point 5 will coincide with point 4.

This value is used to avoid obstacles that are higher than point 3, and that are in the path to the palletizing station.

The most common obstacles are: mechanical elements, photocell assemblies, other palletizing stations, ...

#

Lifting column variables at Pick Station

Once the lift column is enabled in the Robot Preset, these fields will appear in the Pick Station Preset.

#

Lift Z

Position value of the lift column associated to the Pick coordinates of the Pick Station preset. Indicated in millimeters. Only available for collaborative robots.

The Lift Z value of the Pick Station preset is different from the Lift Z value of the Pallet Station preset and the Interlayer Station preset.

#

Inverted Lift Z

Position value of the lift column associated to the Inverted Pick coordinates of the Pick Station preset. Indicated in millimetres. Only available for collaborative robots.