#

Robot preset

#

Description

This preset references the make and model of robot linked to the project.

#

Brand and model

This preset will be associated with a compatible brand and a specific model of robot, present in our database.

When a new project is created and a recipe is accessed for the first time, the brand and model is selected from those available in the Wepall database for that type of project.

Once a license is assigned to a project, and the project status changes to paid, this option is fixed in the project.

For more information, please consult Wepall's technical team.

#

Changing the brand and model of the robot

BRAND AND MODEL CAN ONLY BE CHANGED AS LONG AS THE PROJECT IS NOT PAID. 🚫🗑️

Change can only be made between models and brands of the same Wepall project type.

Once a license is assigned to a project, and the project status changes to paid, this option is fixed in the project.

For more information, please consult Wepall's technical team.

#

Variables

#

Name

User-defined name for the robot.

#

Model

Robot model to be implemented in the project.

#

Controller version

Controller version.

#

Tool signal

Check to enable the gripper control signals through the direct signals integrated by the robot. So that the control would be performed directly by the robot, and not by the PLC.

This function is only integrated in some brands and/or specific models.

#

Only pack points

Check to generate only the pack coordinates in the recipe files, eliminating the rest of the points of the sequence.

This function is only integrated in some brands and/or specific models.

#

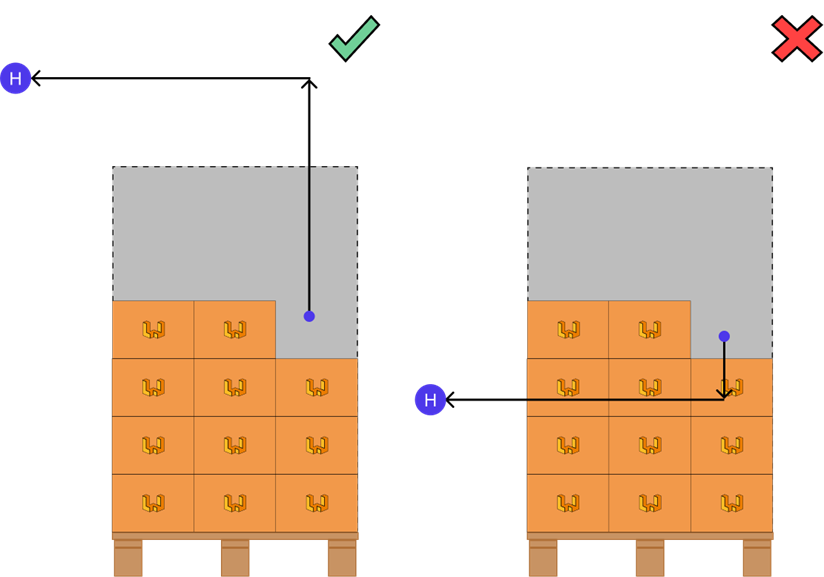

Home(X,Y,Z,R)

Coordinates of the Home point where the robot will be placed in a safe position where it will not hinder the operation of the system.

For more information on how to obtain coordinates, please refer to the obtaining coordinates section of this manual.

#

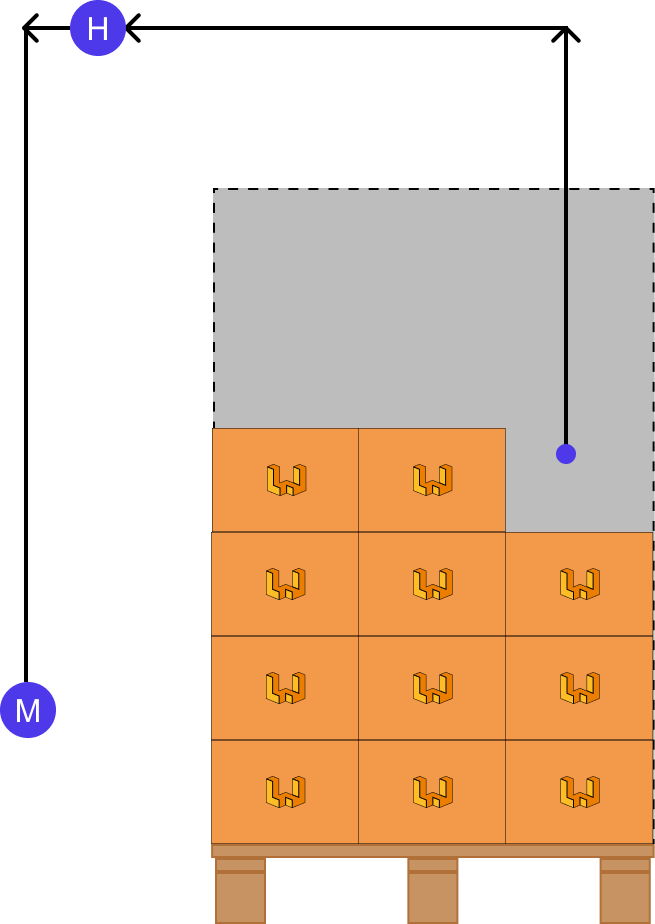

Maintenance(X,Y,Z,R)

Coordinates of the maintenance point where the robot will be located for gripper maintenance tasks.

For more information on how to obtain coordinates, please refer to the obtaining coordinates section of this manual.

#

Lifting column integration

Warning

Only available for collaborative robots

#

Has lifter

Check for lifting column room (auxiliary axis). Only available for collaborative robots.

Warning

Once the lifting column has been enabled in the Robot Preset, these fields will appear in the Presets:

#

Robot Preset

- Max Lift Z

- Home Lift Z

- Maintenance Lift Z

#

Pick Station Preset

- Lift Z

- Inverted Lift Z

#

Pallet Station Preset

- Lift Z

#

Interlayer Station Preset

- Lift Z

- Pack Lift Z

Failure to NOT include the correct values may result in malfunctioning of the installation or collisions.

#

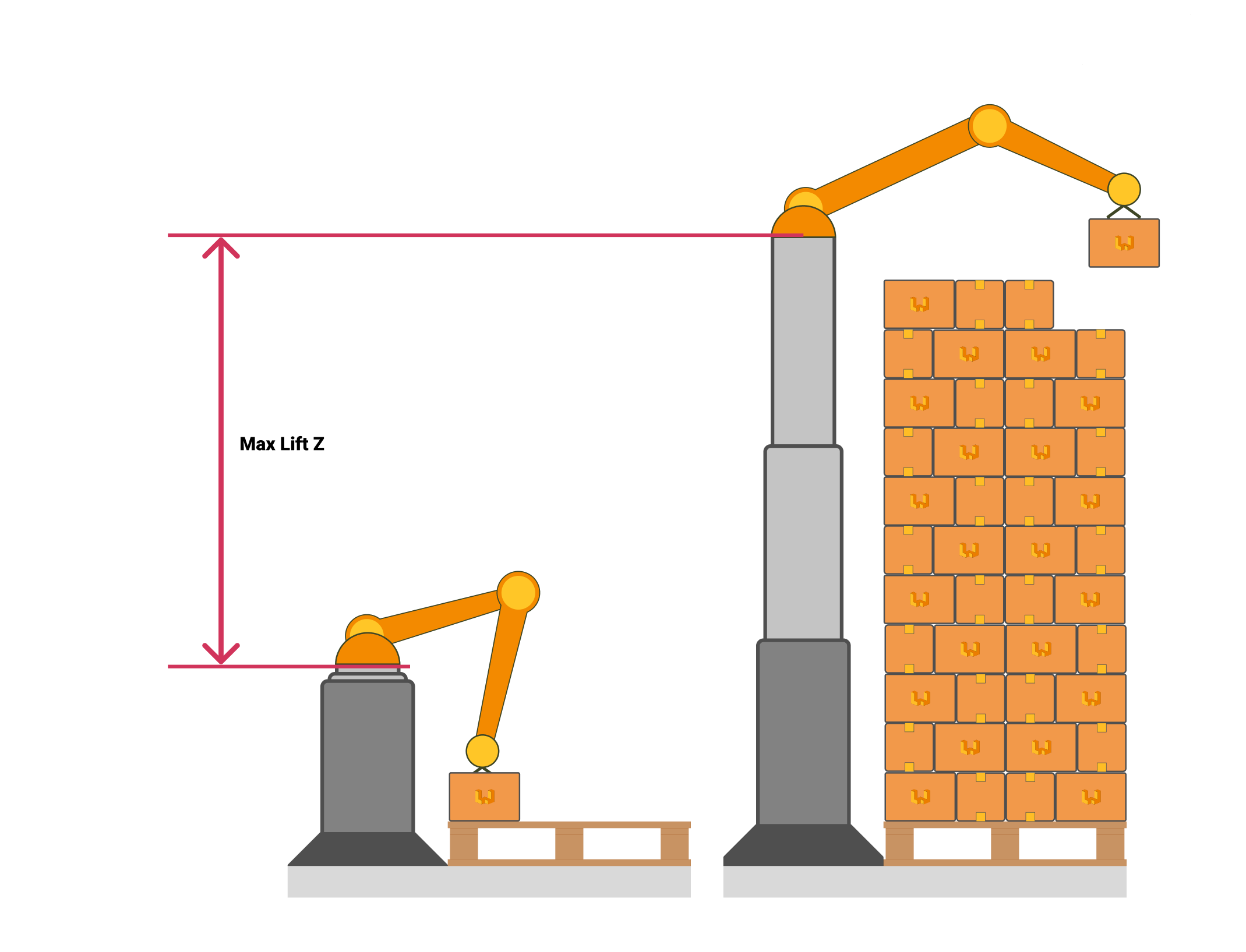

Max Lift Z

Maximum range value of lifting column displacement. Indicated in millimetres. Only available for collaborative robots.

#

Home Lift Z

Position value of the lifting column associated with the Home coordinates of the robot preset. Indicated in millimetres. Only available for collaborative robots.

#

Maintenance Lift Z

Lifting column position value associated with the maintenance coordinates of the robot preset. Indicated in millimetres. Only available for collaborative robots.

#

Lifter

Types of lifting column management. Can be managed directly by the PLC (via communication channel) or directly by the robot (only supported brands).

For more information, refer to the PLC-Robot interaction section of this manual.