#

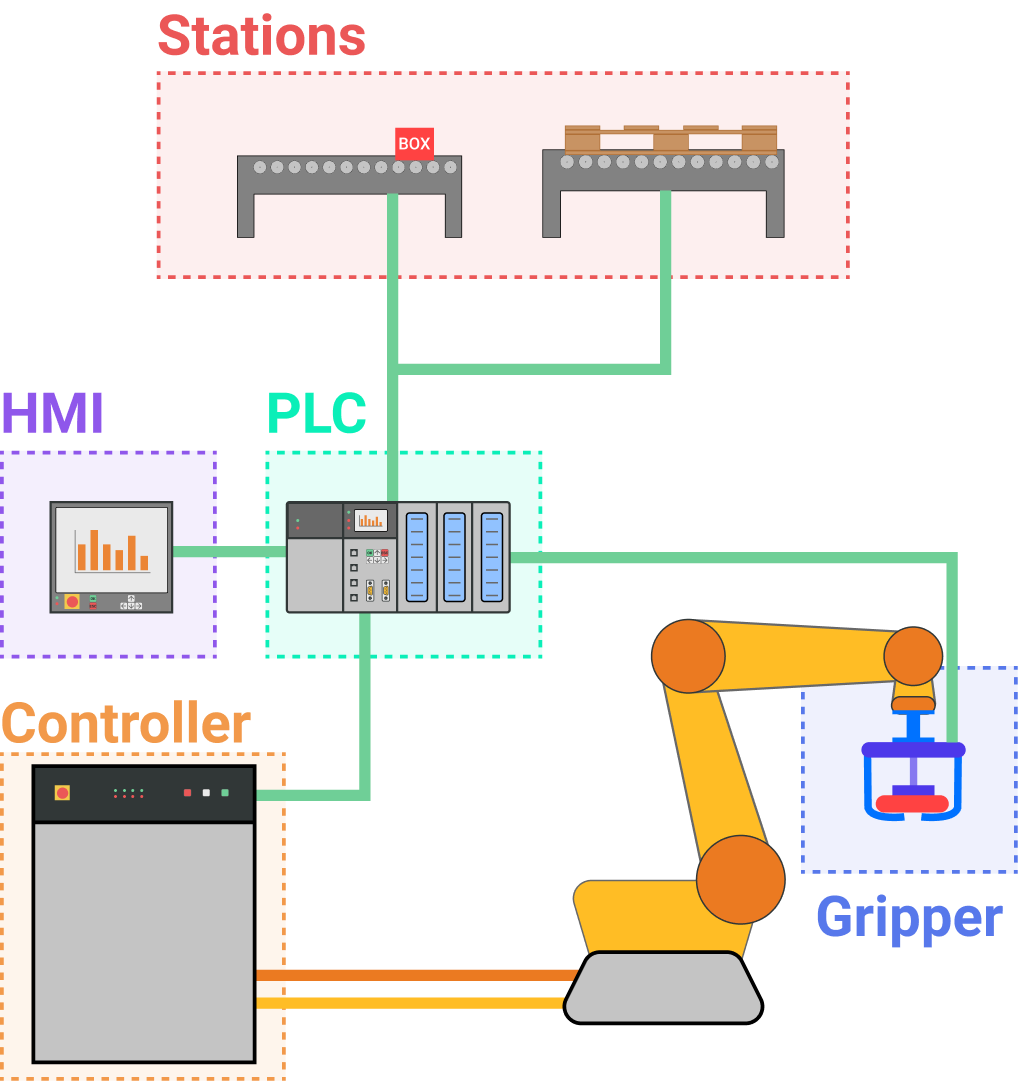

Interaction with PLC

The input/output management will be carried out by the PLC, including the gripper management. By centralizing the decision making in the PLC, a more robust and efficient system is obtained, mainly due to the technical limitations of the control units associated with the robot, in addition to their limited input/output.

The synchronization between the PLC and the robot is the key to the whole installation, as it will determine the reliability of the system. Considering a typical palletizing installation, the following sections will outline the programming of the PLC, and its interaction with the robot.

It is important to take into consideration, when programming the PLC, the delays of the different mechanical systems present in the system. If they are not considered, they can generate malfunctions in the installation. An example of this is the delay in the opening of the gripper when leaving the product on the pallet. If a delay or an associated direct signal is not established, the opening may occur during the return to the pickup, projecting the product and potentially causing damage to the installation, as well as undesired stops. Optimal management of delays will increase the overall productivity of the system, as well as minimize errors that may arise during start-up.

The robot movement is based on point-to-point movements and the succession of these points defines the trajectory to be developed by the robot during the execution cycle. The sequence of points during the palletizing process will depend on the type of gripper to be installed.

The points are calculated by Wepall based on the parameters inserted by the user in the configuration of the nodes and the design of the mosaic.

#

Control of palletizing cell

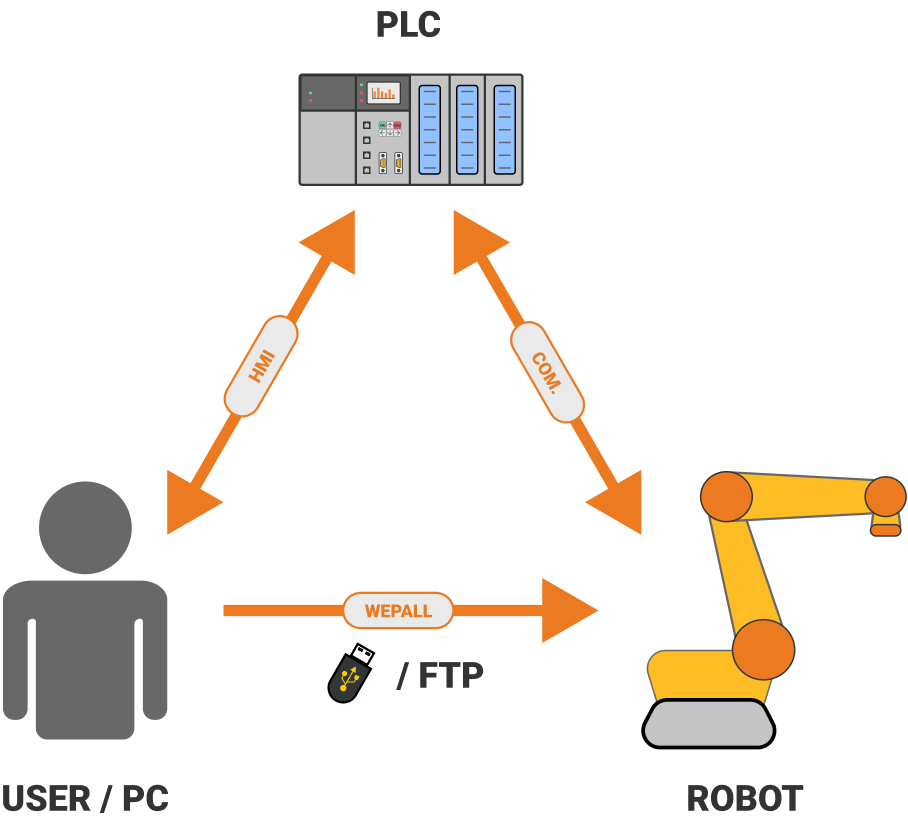

The programs generated by the user with Wepall must be uploaded to the robot through the means established by the robot manufacturer (FTP, USB port, ...).

The program sequence generated by Wepall, as well as the interaction of the signals involved, is a Wepall standard. Therefore, the PLC programming will be in accordance with this standard and the selected program sequence.

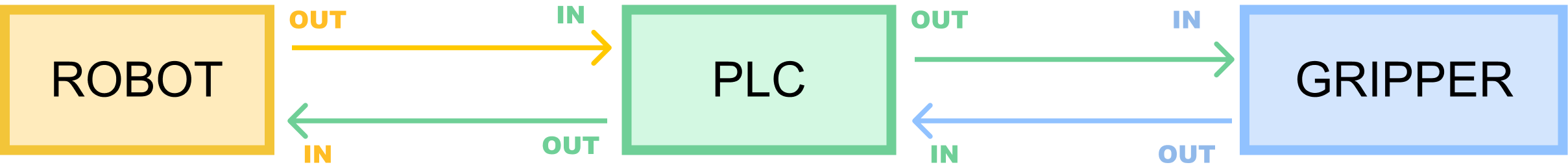

The control of the elements integrated in the system will be carried out by the PLC, including the management of the robot gripper.

warning Warning

If the gripper control is to be carried out directly by the robot and not by the PLC, please consult Wepall's technical department.

The PLC and the robot must be linked by means of an industrial communication protocol, the length of the data frame being conditioned by the elements integrated in the installation, starting from a minimum of 256bits input/output. The transfer speed must be high enough to avoid unwanted delays.

The communication and interaction of signals is defined by Wepall mapping. It relates the Robot inputs to the PLC outputs, and in turn the robot outputs to the PLC inputs.

Note

For more information, refer to the mapping signal description manual and the mapping table (Excel).

#

Management of mapping zones

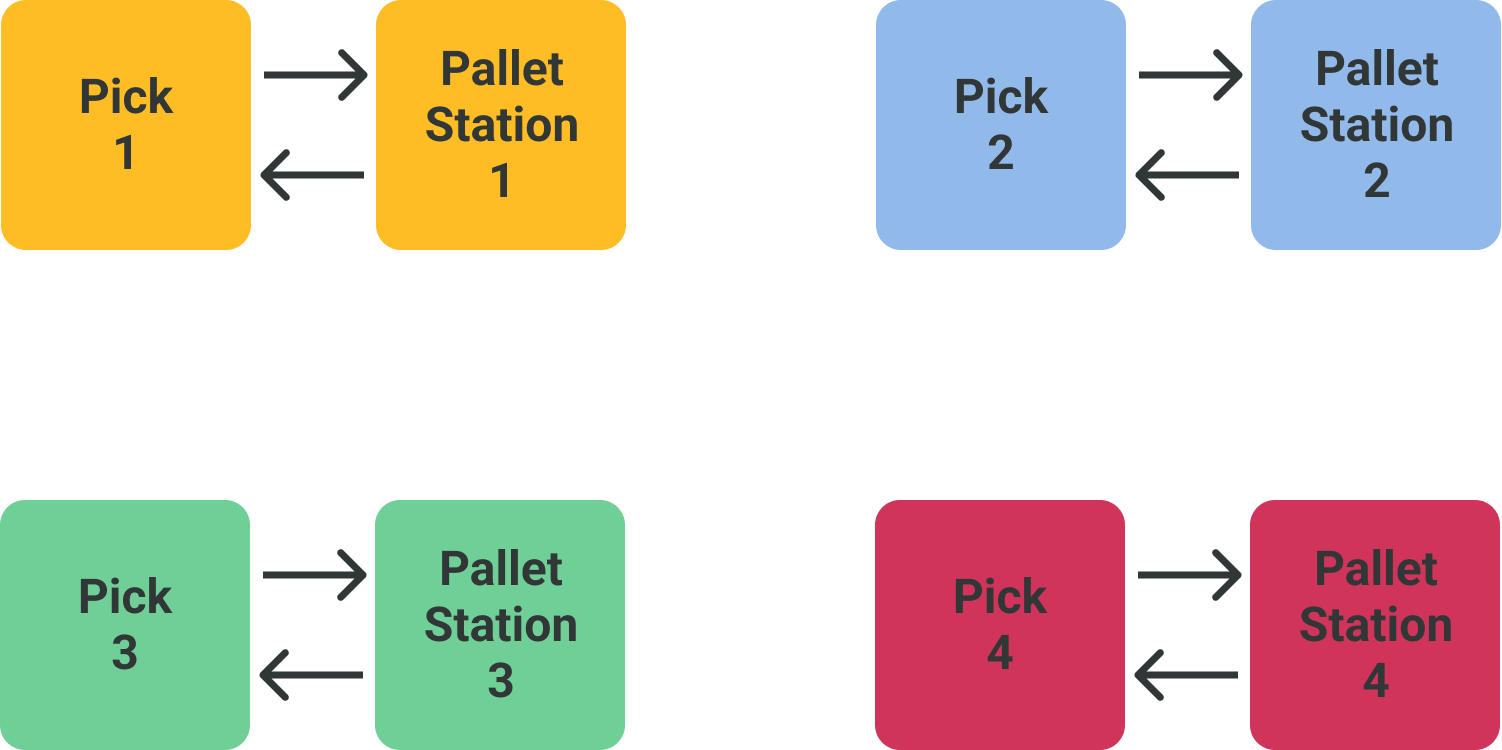

The mapping section in charge of managing the pickup and palletizing station behavior. It is divided into 4 zones, each of which is divided into the following sections:

- Pick, with all the signals involved in the product picking process.

- Pallet Station, with the signals involved in the process of placing the products on the pallet.

The control logic of the 4 possible zones will be independent of the selected zone. The PLC programming must adapt the communication signals involved, depending on the zone value of the selected recipe.

warning Warning

It is not possible to combine the signals involved in the different zones (e.g. Pick 1 - Pallet Station 3).

The choice of the zone is made in the field associated with the Pallet station node. All recipes using this node will use the same selected zone.

Note

For more information, refer to the node configuration and mapping signal description manual.